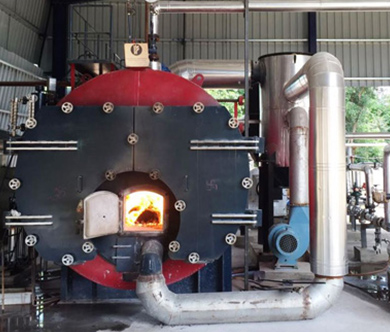

Boilers

Package Boiler Manufacturers

Our multi-fuel package boilers are designed to provide safe and efficient operation, with the capability of firing agro waste and biomass fuels. The external furnace is constructed with four-sided membrane walls, making it durable and suitable for a range of applications. These package boilers are equipped with a shell-type fire tube boiler, utilizing a three-pass wet-back arrangement to generate steam and efficiently cool gases.

The innovative design ensures optimal heat transfer, making the boilers highly efficient and cost-effective. We use advanced technologies to manufacture our multi-fuel package boilers, providing our customers with reliable and easy-to-operate products. Our commitment to quality ensures that the boilers meet the highest standards of performance and durability.

Capacity

5 TPH to 25 TPH

Pressure

10.5 kg/cm2 (g) to 17.5 kg/cm2 (g)

Steam Temperature

Our versatile boilers are capable of generating both dry and saturated steam, precisely meeting the required working pressure for a variety of applications. To further meet the needs of our clients, we also offer the option of producing superheated steam by utilizing a Super Heater to achieve the required working pressure and temperature.

Fuel Fired

Agro Waste/ Bio Mass like wood chips, Bagasse, Saw Dust, Coconut Shells, Ground Nut Shells, Rice husk, Coffee Husk, Palm Shell, Cotton Waste etc